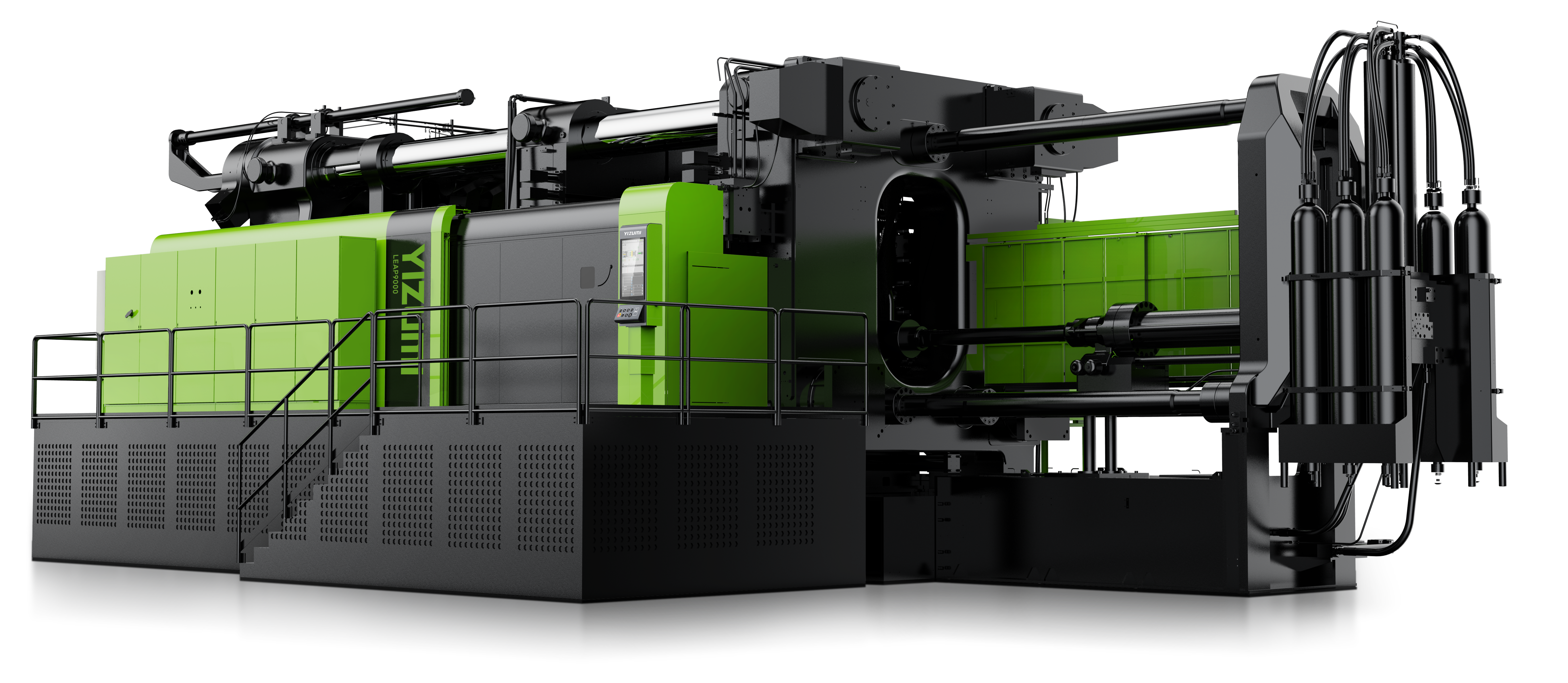

LEAP embodies all of YIZUMI techniological innovation. LEAP die-casting machines (ranging from 380 to 9000 tons of clamping force) are synonymous with efficiency and high levels of OEE (Overall Equipment Effectiveness).

The solutions developed by YIZUMI Yi-CMS & Yi-MES provide customers with high flexibility and setting and managing key processes and production parameters.

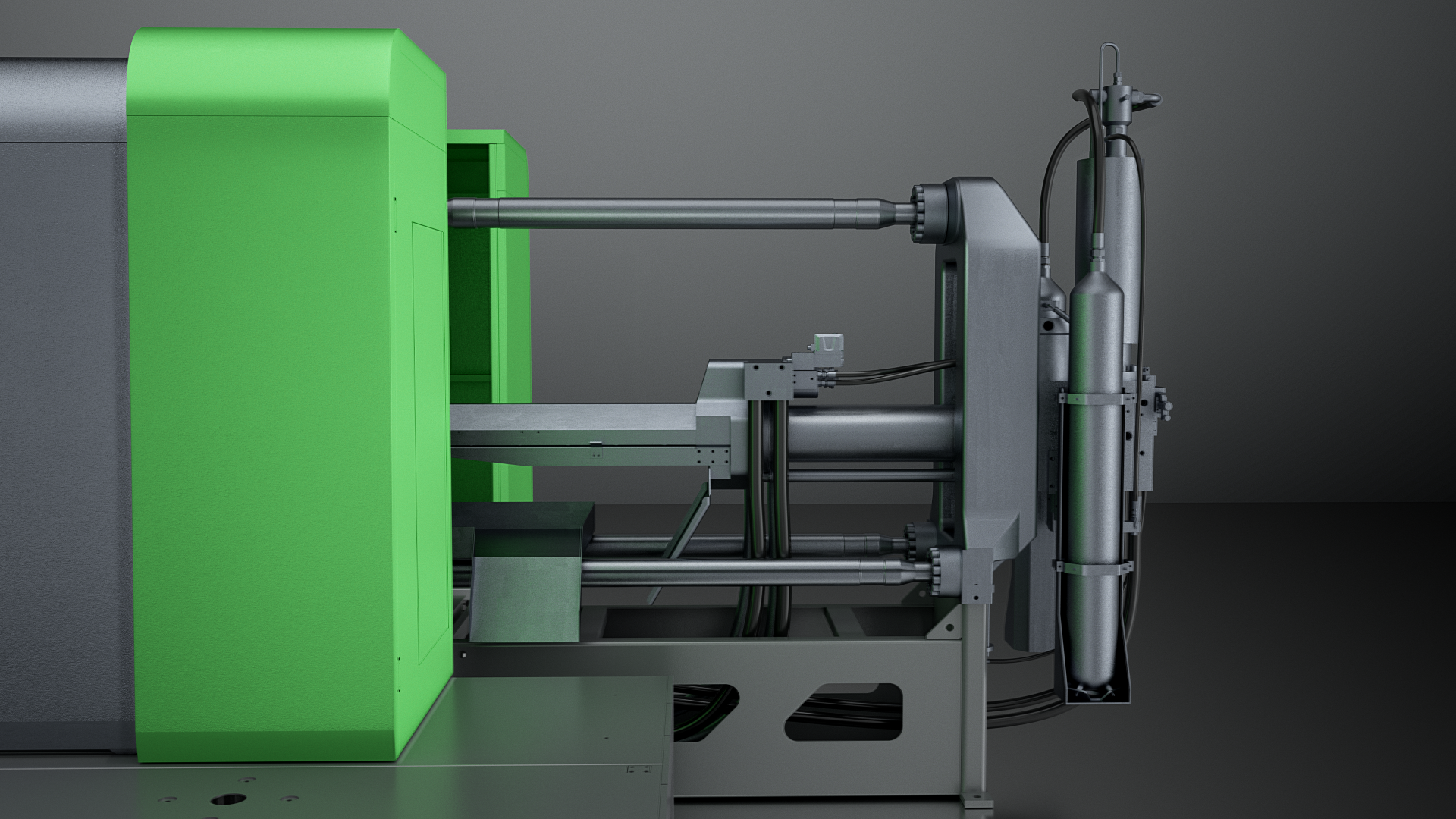

Energy saving and innovative hydraulic

Highly efficient hydraulic components to ensure precise movements, high casting reliability and extended service life. The dynamic servo pump allows significant energy saving

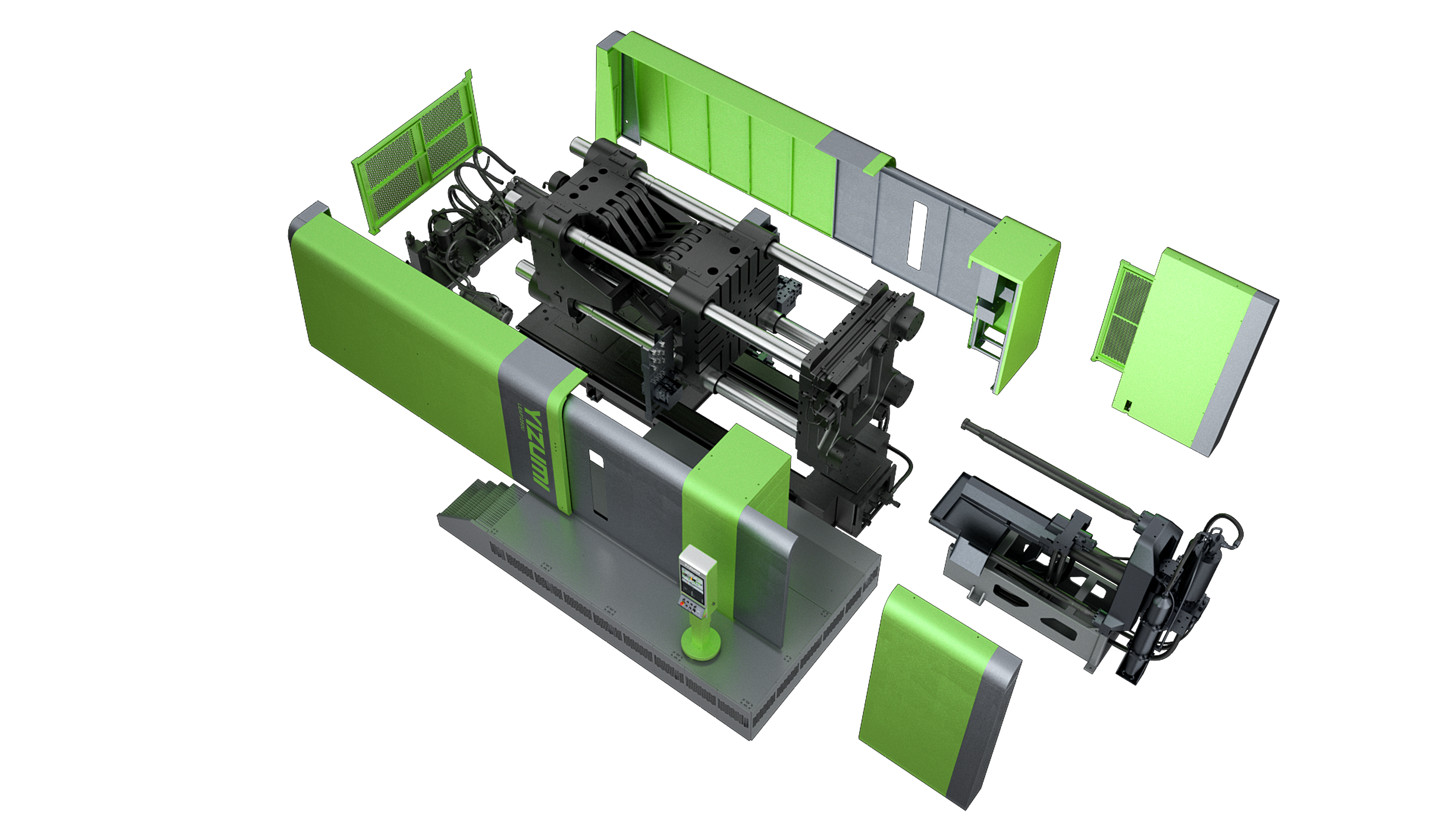

Reinforced and fast clamping system

LEAP clamping system has been designed to ensure fast and accurate movements

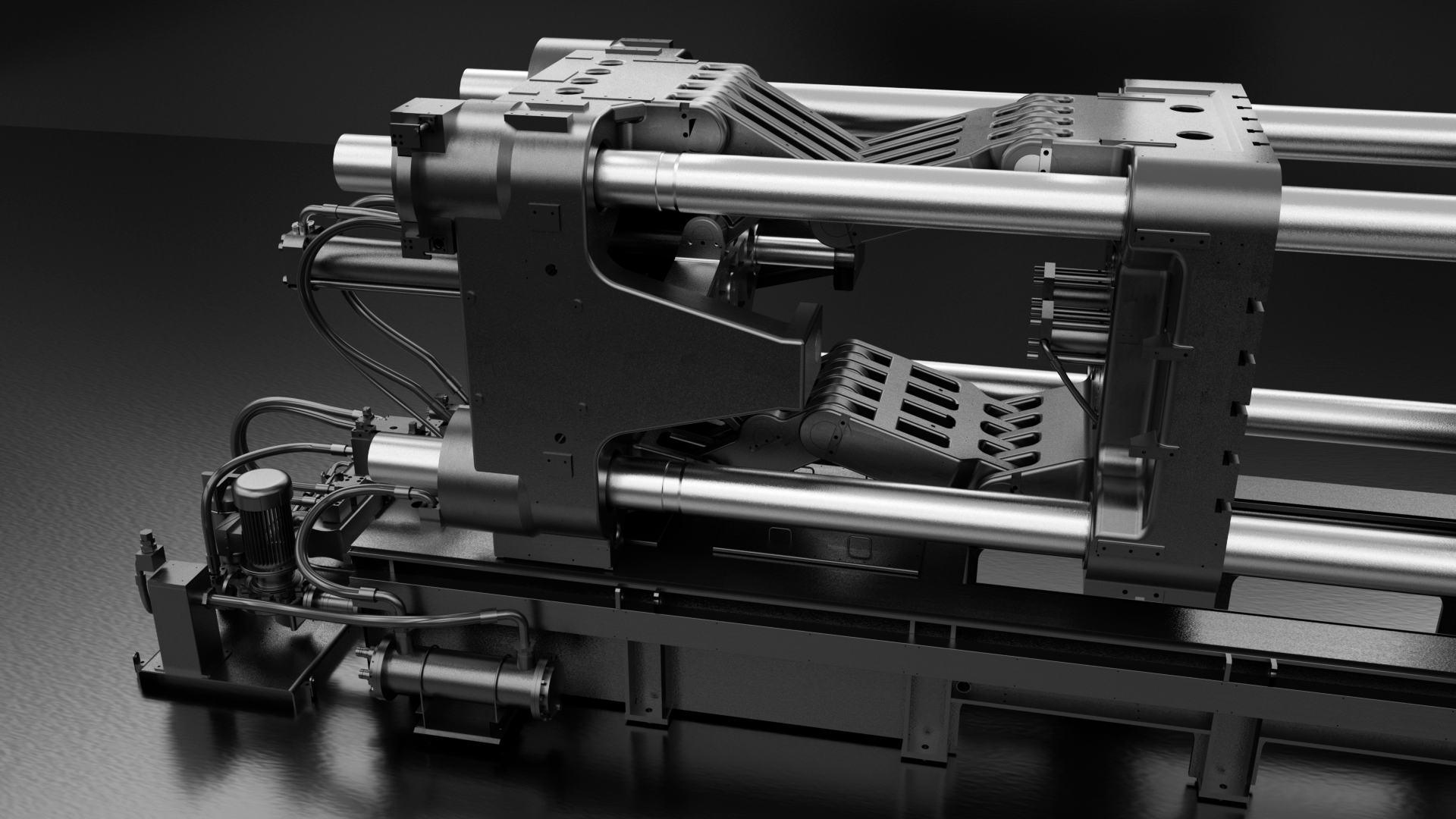

YIZUMI Yi-Cast injection unit: quality with every shot

Through the adoption of the most advanced technologies, the real-time-closed-loop shot control ensures the highest precision and repeatability at every shot

YIZUMI ORCSA-HMI with full performance control

The highly intuitive HMI ORCA allows the full control of all production parameters in an easy and efficient manner

Energy consumption reduction

Faster opening and closing

closing times

Reinforced clamping unit

Completely re-engineered toggle system with increased platens rigidity to ensure an extended service life.

The combination of the renewed clamping unit with the innovative YIZUMI hydraulic system allow users to achieve 10% faster opening and closing times.

The use of servo-motors reduce up to 40% the energy consumption while enuring the same performance levels.

Easy programming of speeds, automatic adjustment of die-height and clamping force strongly contributes to the achievement of very high production efficiency.

Quick and easy adjustments of all functional connections between the die-casting machine and the mould.

RTCL injection system

Programmable segments for each injection phase

The new injection system of LEAP provides the highest performance standards in the die-casting process.

Yi-Cast, il sistema di controllo dell’iniezione proporzionale in anello chiuso, permette di programmare velocità e pressione durante tutte le varie fasi del processo di iniezione. L’RTCL (real-time-closed-loop) identifica tutte le possibili deviazioni da quanto programmato e regola in tempo reale i parametri di processo. Questo garantisce elevata qualità ad ogni stampata attraverso la massima ripetibilità del processo.

- V1 starting point <0,15m/s with repeatibility of ±0,02m/s

- Massima velocità fase V2 >12m/s con accelerazione media >40g

- P3 delay ≤20ms with pressure programmable in 10 segments

Intuitive HMI

New and intuitive HMI. ORCA system enhances and simplifies the die-casting process management.

ORCA control system features an industrial PC and a large multi-touch screen for a quick access to all process parameters, to alarm messages and to preventive maintenance functions.

- Fully digital control of the die-casting machine

- Process parameters and functions

- Monitoring system with alarms and troubleshooting

- Injection control parameters and statistical process control (SPC)